What is Pineapple Fibre

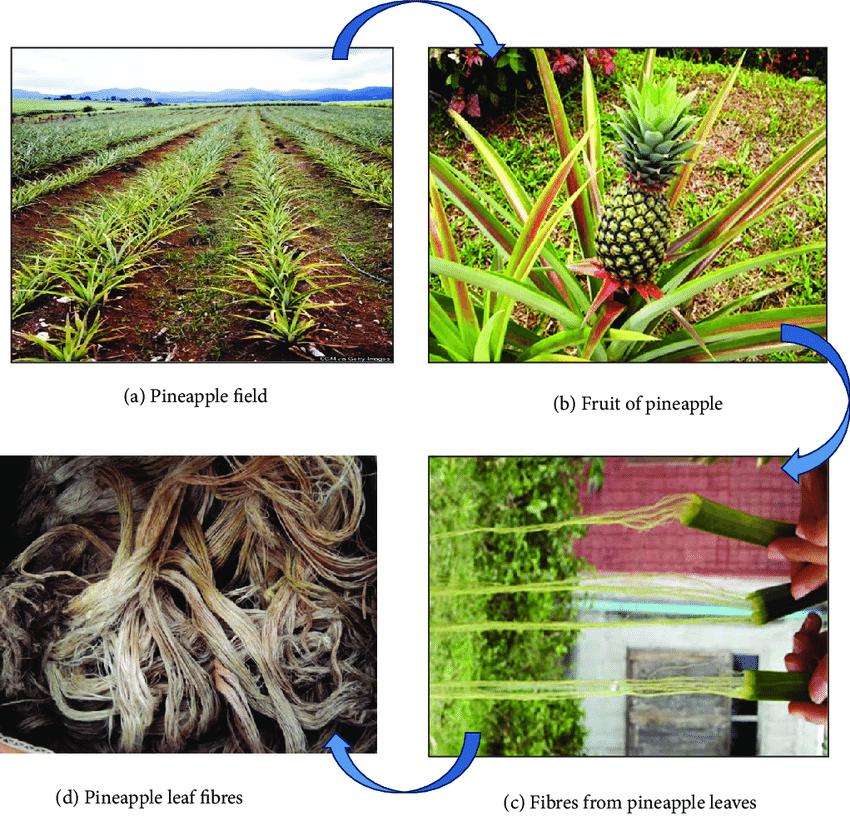

Pineapple fibre is made from pineapple leaves, a by-product of pineapple farming that would be disposed otherwise. This makes it a highly sustainable and renewable resource.

The process of fiber extraction from the pineapple leaf can be done either manually or with the aid of machines. The manual process involves stripping off the fiber from the retted leaf. Fibers of the leaf are scrapped by means of a broken plate or coconut shell and a fast scraper can extract fiber from over 500 leaves per day after which the fibers are washed and dried in the open air.

With this process, the yield is around 2-3% of dry fiber, which is about 20-27 kg of dry fiber from 1 tone of pineapple leaf. After drying, the fibers are waxed to remove the entanglements and the fibers are knotted. During the knotting process, each fiber is extracted singly from the bunch and knotted end to end to form a long continuous strand. The fiber is then sent for warping and weaving.

In the mechanical process, the green leaf is cursed in a raspador machine. The soft green parts of the leaves are crushed and washed in water and the thread is taken out. The thread is then brushed with a comb and fine threads are separated from the spongy ones.

The last step is knotting of the threads by hand and spinning the threads with the help of a charka.

Why is Pineapple Fibre a sustainable material

Being natural and biodegradable, it does not produce microplastic and alleviates pressure on landfills. Production of the fibre is clean, sustainable and compliant.

The most important property of pineapple fiber is biodegradability and noncarcinogenic , with an advantage of being cost-effective. Pineapple leaf fiber is more delicate in texture than any other vegetable fibers. It helps in climate restoration and soil quality by preventing soil erosion.

To produce silky white fiber from pineapple waste using biotechnology.Biotechnological engineering of waste to fiber.

Why we choose Pineapple Fiber material?

A mature plant has about 40 leaves, with each leaf being 1-3 inches broad and ranging in length from 2-5 feet. The average plants per hectare are around 53,000 plants, which can yield 96 tonnes of fresh leaves. On an average one tone of fresh leaves can yield 25 kg of fibers, thus total fiber extraction can be around 2 tonnes of fiber per hectare.The fiber is adequate and used widely. Pineapple fibers are an ivory-white color and naturally glossy. This delicate and dreamy cloth is translucent, soft and fine with a high luster.It has a softer surface and it absorbs and maintains a good colour.pineapple leaf fibre is more compatible natural fibre resource,the fiber can easily retain dyes,Sweat absorbent and breathable fiber,Hard and not wrinkling properties,Good antibacterial and deodorization performances .

Pineapple leaf fiber which is rich in cellulose ,abundantly available ,relatively inexpensive ,low density ,nonabrasive nature,high filling,level possible,low energy consumption ,high specific properties,biodegradability and has the potential for polymer reinforcement